Getting full emptying in a double cone mixer is vital for keeping batch purity, cutting down on waste, and stopping mix ups—especially in tough powder work like powder coating rims. The main idea is to mix good machine setup, right running ways, and knowledge of how stuff acts. By handling these parts together, makers can get smoother and cleaner work with steady item quality.

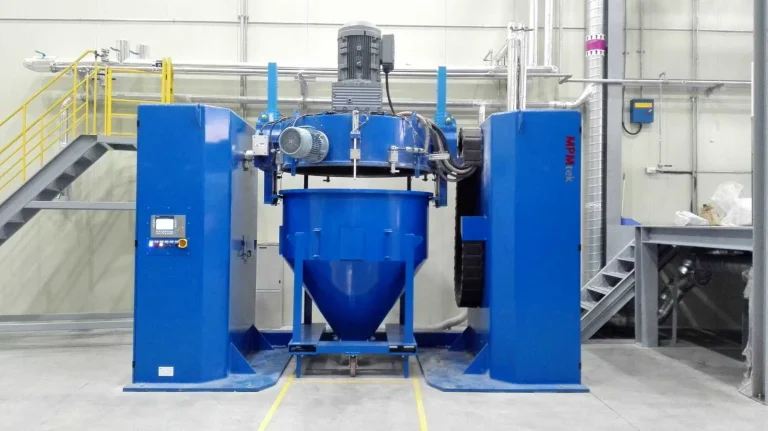

Double Cone Mixer and Its Discharging Mechanism

Key Components of a Double Cone Mixer

Right in the middle of the خلاط مخروط مزدوج sits its two-cone shape. This even design helps with steady blending. It also leads material to the exit spot at the bottom center while turning. The slanted sides of the cones cut back on still areas. They aid pull from gravity, mainly when unloading.

Inside barriers can get added to boost blending by making rough flow as the container spins. A middle spin line makes sure of even motion. This helps with reliable mixing and shifting of powders to the way out.

Valves at the exit point—often butterfly or slide-gate kinds—manage the release of stuff. Their spot and tight close are key to dodge drips or hold-backs.

One more big trait is the surface polish. “Large volume, easy cleaning” and “High automatics” are pluses that come from slick inside areas and top-notch stuff like stainless steel. These work with many powders, including food-safe or lively chemicals.

Common Applications in Powder Processing

Double cone blender can blend crisp, bendy, loose and light stuff. It gets used a lot in fields such as powder coating, medical, dye, fine chemical, fine ceramics, and so on. This flexibility makes it great for powders and bits that flow easy. In jobs like advanced powder coating, where even spread of bits is key—for example in making illusion purple powder coat finishes—this mixer kind gives solid outcomes.

Its soft blending move keeps fragile bits whole. Yet it still gives enough stir for even mixes.

Factors Influencing Discharge Efficiency

Role of Material Characteristics

The type of powder changes how well it flows out of the mixer:

- Powders that flow well empty fast.

- Sticky stuff tends to bunch up. It might need machine help.

- Bit size spread matters: wide spreads can cause splitting, while tiny bits may hang on surfaces.

- Water amount raises sticking and blocking risk.

- Static charge is a big issue in fine powders like those for powder coating rims—it makes bits stick to inside areas.

These features must get checked before picking or running a mixer.

Impact of Mixer Design Parameters

Emptying action gets much better when setup factors are tuned right:

- Cone slant: sharper slants boost gravity tug to the exit port.

- Size hold: should fit work needs—too full leads to spotty blending; too empty cuts output.

- Exit valve spot: middle bottom ways out make sure even flow.

- Inside shape: “Radial/axes and side mixing” makes sure level spread in the cone.

- Surface bump: shiny insides lower rub and stuff pile-up. Slick shifts between cone parts dodge stuff getting stuck.

Each of these bits counts in getting clean emptying.

Influence of Operational Settings

Running settings can fix or wreck emptying output. Spin speed needs to be just right—not too quick to make ring layers, not too poky to block good flow. Blending time should be enough for sameness without getting too hot or grinding bits too much.

Fill amount must stay in 40–70% of full size for best roll action. Surround controls like heat and damp affect powder acts; very key when dealing with damp-touchy coatings like illusion purple powder coat.

Techniques to Achieve Complete Discharge

Modifying Material Properties for Improved Flow

Sometimes, early prep is needed. Drying powders before putting in cuts bunching. Putting in flow helpers or anti-bunch adds boosts emptying acts in sticky stuff.

This helps a ton with pricey special coatings like illusion purple powder coat that bunch in wet spots.

Enhancing Mixer Construction Features

Boosts or setup changes can lift output:

- Shiny inside areas cut bit sticking and make cleaning simple.

- Sharper cone slants let better gravity help flow.

- Bigger or air-pushed exit ports lower stuff hold at the valve.

For makers who handle clingy or static-loaded powders, these shifts can mean tidier work with less stop time.

Optimizing Process Parameters During Operation

A couple of running tips can change things a lot. Changing spin rounds before emptying pushes powder shift to the way out. Managed start-stop runs help free stuck bits, mainly at edges or valve sides.

In auto setups like those from MPMtek, tweakable PLC controls make it simple to do such changes right. Touch screen PLC control adds bend in on-spot work.

Auxiliary Methods for Improving Discharge Performance

Application of External Vibration Systems

Putting on shake motors or pads can well knock off left stuff:

- These can sit on mixer legs or sides.

- Smart spots make sure shake spreads well without hurting build strength.

This works great when emptying super fine powders used in top jobs such as powder coating rims.

Implementation of Pneumatic or Vacuum-Assisted Systems

These setups make push differences at the exit port:

- Pressed air blasts push last bits to the way out.

- Suck pull helps take out tough stuff without hand scrape.

Both ways cut work and lift clean in ruled fields like drugs or food making.

Importance of Routine Maintenance Practices

Regular upkeep keeps setups going smooth:

- Usual checks stop pile that could jam ways out.

- Clean steps wipe out mix-up risks between loads.

- Wear looks make sure valves and seals keep working fine.

Easy steps—done often—can stop big troubles later.

Integration with Powder Coating Processes

Compatibility with Advanced Powder Coating Materials

Dealing with special powders needs care. Illusion purple powder coat, for instance, is touchy to dirt and water. Making sure full emptying means each load keeps its planned color shade and bit spread.

MPMtek, as a focused industrial machinery supplier centered on معدات طلاء مسحوق manufacturing, gives fitted answers to manage such stuff well across all steps—from blending to push-out to after-hard systems.

Enhancing Product Quality Through Efficient Mixing and Discharging

When mixers empty all the way:

- Recipe rightness gets better due to full get-back of blended parts.

- Load tracking stays whole—a must in ruled fields.

- Item wastes get cut, raising gains.

For jobs like powder coating rims where surface look and color sameness are key, every bit counts.

الأسئلة الشائعة

Q: What causes incomplete discharge in a double cone mixer?

Stuff cling, bad flow, wrong spin speed, or not-great mixer shape can all add to it.

Q: Can I process sticky powders in a double cone mixer?

Yes, but you might need to use flow aids, add shake help, or change inside areas for better output.

Q: How often should I clean the mixer?

Best after each load—mainly when changing stuff—to stop dirt and pile.

Q: Is vacuum-assisted discharge safe for all materials?

Mostly yes, but make sure your powder isn’t lively or touchy to push shifts. Check your stuff safety sheet.

Q: Why choose MPMtek for powder coating equipment?

MPMtek focuses on building trusty machines that back every step of powder coating making—from blending to hardening—with field know-how.