Cone mixers, also known as double cone blenders or twin shell blenders, are workhorses in industries ranging from pharmaceuticals to chemicals and plastics. If safety isn’t built into every stage of their design, the dangers can quickly outweigh the gains. From stopping dust blasts to cutting worker contact and machine breakdowns, the proper safety steps are not just rules to follow—they’re vital for steady work over time and keeping products in good shape.

Overview of Double Cone Blenders in Industrial Applications

Functional Role in Powder Processing

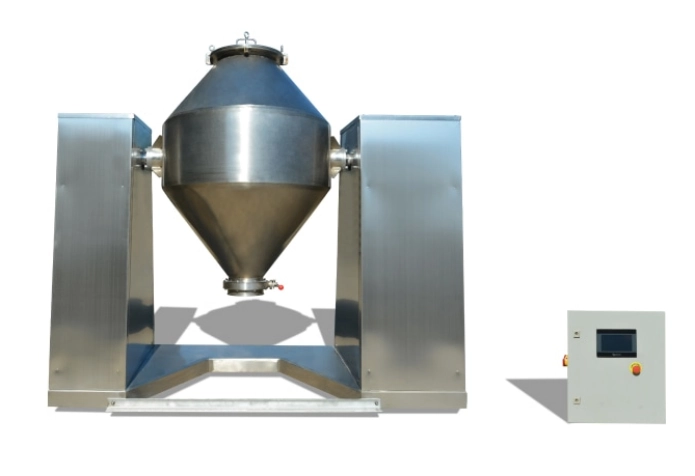

Double cone blenders are commonly used for mixing dry powders and granules in fields that need accuracy and steadiness, such as drugs, chemical work, and powder coating. Their spinning cone shape gives full side-to-side and up-and-down mixing. This works well for stuff that is brittle, flexible, free-flowing or not heavy.

Cone mixers can mix crisp, ductile, loose and light materials. This steady blending makes sure particles spread evenly. And that’s key for next steps like pressing, pushing out or covering. For instance, in powder coating, poor mixing can cause color differences or uneven layers.

Common Operational Challenges

Even with their pluses, double cone blenders bring certain problems:

- Risks of mixing batches wrong if cleaning isn’t enough.

- Dust buildup during filling and emptying raises breathing dangers and makes risky spots.

- Wear from constant turning and rough materials can weaken the build over time.

These issues show why it’s key to add industrial safety gear and steps right into the blender setup.

Structural Safety Features in Modern Double Cone Blenders

Reinforced Construction Materials

To deal with rough or reactive powders, current blenders use top-quality stainless steel or alloys that fight rust. These materials last long and are simple to clean.

Smooth internal surfaces to minimize residue accumulation and facilitate cleaning. This even finish cuts down on material sticking—a common cause of dirt and uneven batches.

Pressure Relief and Vacuum Integrity Systems

Many blending jobs use vacuum setups to stop oxidation or boost mix quality. Modern units have pressure relief valves to avoid too much pressure and keep inner balance safe. Built-in pressure relief valves to prevent overpressurization during vacuum blending.

Plus, sealed designs guard vacuum strength by stopping unwanted air from getting in. This is a big deal when dealing with powders that hate moisture or can catch fire.

Operator Safety Measures Integrated into Blender Design

Interlock Mechanisms for Access Control

To shield workers from hitting moving parts by mistake, safety locks are a must. These setups make sure doors stay shut until spinning stops fully and power is off.

Doors or hatches remain locked until the blender is fully stopped and de-energized. These parts are extra important during cleaning or fixes, when a sudden start could lead to big trouble.

Emergency Stop Systems and Manual Overrides

Emergency stop setups are now basic in industrial safety gear. Placed where workers can reach them fast, these let you halt things right away if something odd happens or in a crisis.

Manual overrides add more control during fixes or power outs—so no worker gets stuck without choices.

Automation and Control System Safeguards

Programmable Logic Controllers (PLCs) with Safety Protocols

Today’s twin shell blenders often come with PLCs that watch blending details like speed, force and heat. If any detail goes over set limits, auto shutdown steps start right away to stop damage or unsafe spots.

Human-Machine Interface (HMI) with Alarm Functions

Live warnings on HMI screens tell workers about problems like door errors, motor overloads or weird shakes. Touch screen PLC control makes these warnings easier to get while leading staff through safe steps from start to end.

Brands like MPMtek, a professional supplier of powder coating production equipment, have incorporated these standards across their high-end machinery lines.

Dust Control and Explosion Prevention Features

Sealed Loading/Unloading Systems with Dust Extraction Ports

Dust isn’t just a mess—it’s a danger. Closed systems with extraction spots cut down on particle spread during filling and emptying.

This lowers worker contact and stops buildup of dust that can burn in the work area—a real boost for safety on the job.

Compliance with ATEX or NFPA Standards for Combustible Powders

When working with powders that can burn, following ATEX (EU) or NFPA (US) rules is a must. This means using motors that won’t explode and grounding all metal bits to dodge static sparks.

The ACM PSR series PSR11 explosion-resistant micro powder pulverizing system is designed and manufactured according to relevant standards of China (GB) and the EU (EN), and meets the relevant standards of PSR11 pressure shock resistance design strength.

MPMtek’s commitment to safety, automation, efficiency and environmental protection reflects its focus on compliance across international markets.

Cleaning, Maintenance, and Contamination Prevention Safety Features

Clean-In-Place (CIP) Compatibility for Hygienic Operations

To skip hand cleaning—which often puts workers near leftover stuff—many units have Clean-In-Place systems. Built-in spray nozzles wash inner surfaces well without taking things apart.

This not only keeps batches clean but also cuts down on fix time a lot.

Tool-Free Disassembly Components for Safe Maintenance Access

Where you need to take apart, tool-free systems with quick clamps make it safer and faster. Workers can pull off parts for checks without special gear or lots of training.

Again, these features help cut downtime while sticking to safety rules—a little gain that builds up.

Regulatory Compliance and Certification Considerations

Adherence to OSHA, CE, and ISO Safety Guidelines

Machines in work settings must match area rules like OSHA (US), CE (EU), or ISO standards. These make sure the build is strong and runs safe in normal or odd cases.

The design and structure of the pre-mixer, extruder, tablet press, ACM micro powder pulverizing system and bonding machine meet the requirements of relevant EU standards (Low Voltage Electrical Directive 2014/35/EU, Machinery Directive 2006/42/EC).

Documentation and Training Support Provided by Manufacturers

Good paperwork—including full user guides—and planned training help workers know how to use all features safely. This is key for cutting risks over the machine’s whole life.

Questions fréquentes

Q: What materials are suitable for blending in a double cone blender?

Dry powders and granules including crisp, ductile, loose or light materials—commonly used in pharmaceutical, food and powder coating industries.

Q: How does a double cone blender prevent cross-contamination?

Through smooth internal surfaces, Clean-In-Place systems, and tool-free disassembly that allow thorough cleaning between batches.

Q: Are modern blenders explosion-proof?

Yes—when handling combustible powders, certified designs include explosion-proof motors and grounded components compliant with ATEX or NFPA standards.

Q: What role do PLCs play in blender safety?

PLCs monitor operational parameters like speed and torque; they automatically trigger shutdowns if unsafe conditions are detected.

Q: Does MPMtek provide support after equipment installation?

Yes. They provide detailed documentation and operator training programs that support safe equipment use across its lifecycle.