Introduction – Choosing the Right Powder Coating Mixer

Picking the right mixer matters a lot in powder coating production. It directly impacts the final coating quality, how fast you can produce, and overall costs. Get it wrong, and you might deal with uneven mixes or wasted time. This article compares high speed mixers and container mixers, two common options. We’ll break down their features to help factories decide.

Exploring High Speed Mixers

What Is a High Speed Mixer?

A high speed mixer blends materials quickly, often used for epoxy polyester static electricity powder coatings. It works by agitating lumps at low speed first, then ramping up to high speed for thorough mixing. Materials form a three-dimensional fog eddy flow ring under the agitator’s effect. This setup suits industries like powder coating, pharmacy, food, dyes, and building materials. In powder coating lines, it’s ideal for creating uniform blends that improve coating performance.

Key Advantages of High Speed Mixers

These mixers cut down on mixing time, handling large batches efficiently. They ensure pigments and additives disperse evenly, which is crucial for consistent color and texture in coatings. For factories pushing high volumes, this means smoother operations and less downtime. Plus, the adjustable mixing time lets operators tweak as needed. Perfect sealing prevents leaks, and it’s simple yet highly efficient. Yeah, sometimes the noise is a bit much, but that’s common in heavy-duty equipment.

Potential Limitations

They guzzle more energy, especially during those high-speed runs. Maintenance can get tricky with all the moving parts. Heat builds up, and noise levels might require ear protection in the shop. Not every setup handles that well without extra ventilation.

Exploring Container Mixers

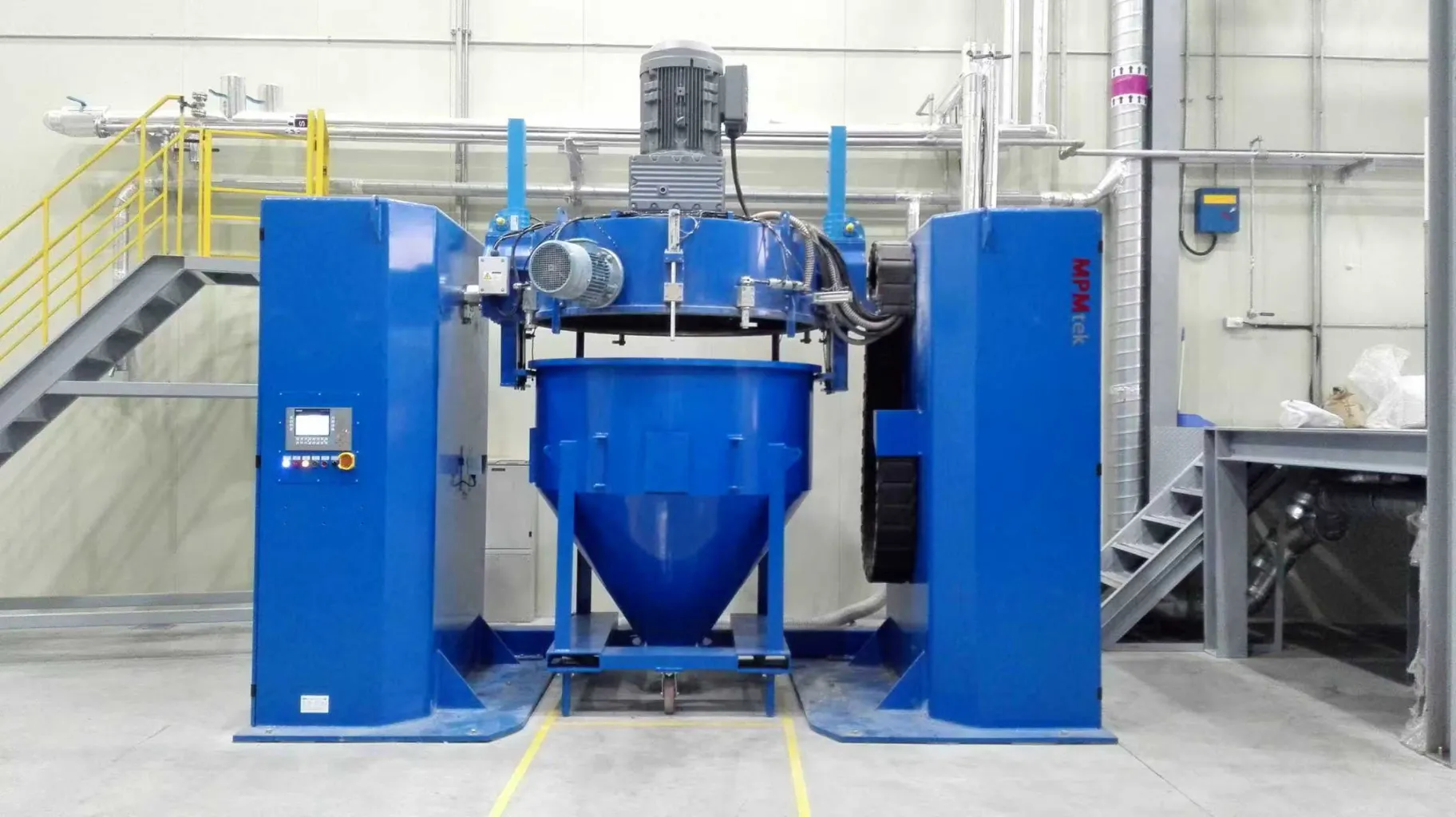

What Is a Container Mixer?

Container mixers are offline machines with movable bins for mixing raw materials. You load the container, push it to the station, and it lifts, connects, and locks to the mixing head automatically. The head tilts 180 degrees while stirring and crushing at high speed for a homogeneous mix. Once done, it returns to position and separates. Controlled by PLC and HMI, it’s flexible for production. Great for batches where you need to switch colors or clean up fast.

Key Advantages of Container Mixers

They mix efficiently and evenly, with multi-containers for easy operation, cleaning, and color changes. Double seals on the shaft stop powder leaks and solidified particles. Options like a cooling water jacket for the mixing head keep things stable. Automatic dust vacuum helps too. The PLC and HMI automate control, and there’s a solid safety system. Maintenance is straightforward, with high reliability. Suited for setups where you juggle different runs without hassle.

Potential Limitations

Mixing takes longer compared to high-speed models. Throughput isn’t as high, so for massive production, it might slow you down a touch. But hey, that gentleness preserves delicate formulations.

Side-by-Side Comparison: High Speed Mixer vs Container Mixer

Let’s stack them up. High speed mixers shine in mixing efficiency, blasting through batches with that eddy flow for quick, uniform results. Container mixers, though slower, offer homogeneous mixes without overworking materials. On batch time, high speed wins for large loads; containers handle smaller ones better.

Energy consumption? High speed mixers use more power due to intense agitation, bumping up operational costs. Container mixers are gentler, often with options like cooling jackets to manage heat, potentially saving on long runs.

For maintenance and cleaning, containers edge out. Easy to swap bins, no leaks from double seals, and simple dust vacuum. High speed ones need more checks on seals and agitators, though they’re efficient overall.

Flexibility wise, containers rule with their offline setup and multi-bin use, perfect for changing colors or specialty mixes. High speed mixers focus on high-throughput applications like powder coatings or dyes.

Both impact powder coating quality positively. High speed ensures perfect dispersion; containers reduce degradation risks. Here’s a quick table to visualize:

| Aspect | High Speed Mixer | Container Mixer |

| Mixing Efficiency | High, with eddy flow for uniformity | Efficient and homogeneous, tilt mechanism |

| Batch Time | Faster for large volumes | Longer, but flexible for batches |

| Energy Consumption | Higher, due to speed | Lower, with cooling options |

| Maintenance & Cleaning | More complex, but effective seals | Easier, multi-containers and vacuum |

| Flexibility | Suited for high-throughput | High utilization, easy color change |

| Quality Impact | Uniform pigment dispersion | Gentle on materials, no leaks |

This comparison shows how each fits different needs. Sometimes factories overlook noise in high speed units, but it’s worth factoring in worker comfort.

Factors to Consider When Choosing a Mixer

Think about production volume first. High batches? Go high speed. Smaller or varied? Containers work. Formulation matters too; sensitive powders benefit from gentle container mixing.

Factory layout plays a role. Container mixers need space for moving bins, but integrate well with automation via PLC. High speed ones fit inline production better.

Budget and ROI: Initial costs vary, but consider long-term energy and maintenance. How it links with extruders or ACM mills is key for seamless lines.

Don’t forget scalability. If expanding, pick something adaptable. Oh, and safety features like comprehensive protection in containers add peace of mind.

MPMtek Mixer Solutions in Action

MPMtek, a maker of powder coating equipment, has deployed high speed mixers in busy factories churning out static electricity coatings. One setup mixed epoxy polyester blends rapidly, boosting output by handling fog eddy flows for even dispersion. Operators adjusted times easily, cutting waste.

For specialty coatings, MPMtek’s container mixers shone in a plant switching colors often. The offline design with automatic locking and tilting let them clean bins fast, no leaks from double seals. Dust vacuum kept the area tidy. In both cases, MPMtek guided selections based on throughput and formulations, ensuring smooth integration.

These examples highlight real-world wins. Factories reported better efficiency after tweaks, though one mentioned initial training on PLC helped a bunch.

Conclusion – Choosing the Mixer That Fits Your Factory

High speed mixers excel in speed and volume, ideal for uniform, high-output runs. Container mixers bring flexibility, ease, and gentleness for varied production. Weigh your batch sizes, costs, and layout. Test a demo if possible. The right choice boosts quality and cuts headaches down the line.

FAQ Section

Q1: Can a factory use both high speed and container mixers?

Yes, many do for different lines. High speed for bulk, containers for specials.

Q2: How does mixer choice affect pigment dispersion and coating quality?

High speed ensures even spread via eddy flows. Containers mix gently, preserving integrity without degradation.

Q3: Which mixer is more energy-efficient for long-term production?

Container mixers often win, with lower power draw and cooling options.

Q4: How does MPMtek customize mixers for different powder coatings?

They tailor features like seals, vacuums, and controls to match formulations, ensuring no leaks or uneven mixes.

Q5: Are container mixers suitable for high-volume production?

They’re flexible but better for medium volumes. For ultra-high, pair with multiples or opt for high speed.