A powder coating crusher’s crushing chamber design plays a pivotal role in determining the efficiency, particle size control, energy usage, and durability of the entire system. Simply put, the geometry and flow characteristics inside the chamber directly affect how well the material is processed and how smoothly it integrates with the rest of the production line. If you’ve ever wondered why two crushers with similar motors perform drastically differently, chances are the answer lies in the chamber.

Overview of Crushing Chamber Design in Powder Coating Crushers

Key Functions of the Crushing Chamber

The crushing chamber is where raw or semi-processed materials are broken down into chips or powder. It defines the physical space in which crushing occurs and establishes how materials flow and interact with internal surfaces. A well designed chamber:

- Controls how material is fed, crushed, and discharged

- Influences throughput rate and energy consumption

- Ensures consistent particle size for downstream processing

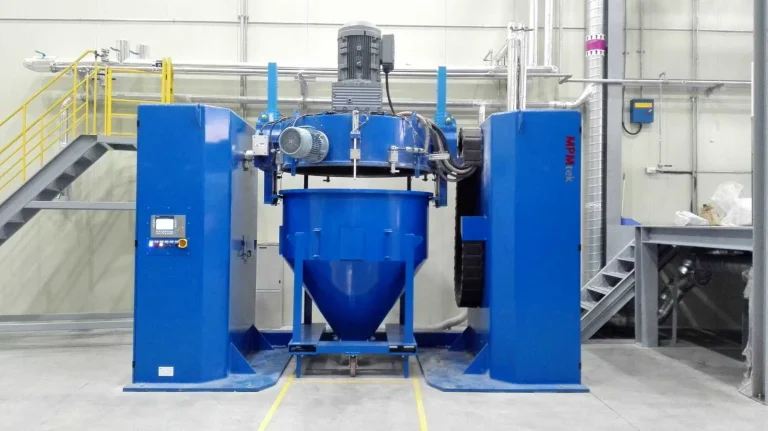

The compact cooling crusher from MPMtek is an example of thoughtful chamber integration. Compact cooling crusher is composed of cooling roller, cooling drum, artificial rubber conveyor and crusher. In this system, the crusher component is tightly linked to upstream cooling mechanisms, emphasizing the importance of spatial design.

Common Types of Crushing Chamber Designs

Crushing chambers can vary significantly depending on the application:

- Flat chambers allow for uniform reduction but may lack efficient flow.

- Curved chambers promote better circulation of material, reducing accumulation zones.

- Multi-stage designs introduce sequential crushing zones for controlled particle size distribution.

Choosing between these depends largely on your production goals and coating material.

Impact on Particle Size Distribution

How Chamber Geometry Affects Final Powder Granularity

Chamber width and shape strongly influence the size range of crushed particles. Narrower chambers typically apply higher pressure per unit area, leading to finer particles. However, they may increase wear rates or clogging if not balanced properly.

On the flip side, wider chambers facilitate smoother material entry but may yield inconsistent particle sizes if flow patterns are uncontrolled.

Role of Internal Flow Patterns in Size Control

Internal turbulence and vortex zones can either aid or hinder reduction. In poorly designed chambers, stagnation zones cause oversized particles to bypass effective crushing. Optimized designs create predictable flow paths that maximize contact between particles and crushing surfaces.

MPMtek’s equipment shows attention to this detail. Chip thickness is adjustable and size is uniform. This implies that both geometry and process control help maintain consistent output granularity.

Effect on Crushing Efficiency

Energy Utilization in Different Chamber Configurations

Energy efficiency isn’t just about motor horsepower—it’s about how that power is used. In a streamlined chamber, energy is concentrated on fracturing particles rather than overcoming friction or compensating for poor flow.

Efficient chambers reduce energy waste per kilogram of product. Meanwhile, awkward angles or sudden transitions increase mechanical resistance and thermal buildup, driving up operational costs.

Material Throughput and Processing Speed Considerations

Faster processing depends on unimpeded material movement. A well aligned chamber maintains momentum through the system, reducing downtime and back pressure.

According to MPMtek, Cooling drum is designed to big size for high cooling efficiency and low operation cost. While this refers to cooling, it demonstrates a design philosophy where spatial efficiency boosts performance—a principle that also applies to crushing zones.

Influence on Wear and Tear of Crusher Components

Contact Points and Abrasive Stress Zones

Material repeatedly impacts specific surfaces within the crushing chamber. High stress zones near sharp corners or narrow throats experience more wear. Concentrated impact areas shorten part lifespan and increase replacement frequency.

Even with durable materials, uneven design accelerates wear. Adjustable liners can help—especially when they’re easy to replace without dismantling the machine.

Impact of Material Flow on Component Lifespan

Turbulent or bouncing flow increases friction between particles and chamber surfaces. This leads to higher abrasion rates on both moving parts and static walls. In contrast, smooth laminar flow extends equipment life by minimizing unnecessary contact.

Easy clean and maintenance in MPMtek crushers suggests that component access and layout are optimized not only for operation but also for longevity.

Operational Stability and System Integration

Vibration and Noise Levels from Different Designs

Unbalanced or asymmetrical chambers can induce machine vibration during operation. This not only causes noise but also contributes to mechanical fatigue over time.

Balanced designs distribute load evenly across rotating parts. The result? Quieter operation and longer service intervals. It may seem like a small win until you’ve worked next to a rattling machine all day.

Thermal Management Within the Crushing Zone

Crushing generates heat—sometimes more than expected. Poor chamber ventilation traps hot air, affecting both performance and component integrity. On the other hand, clever geometry can enhance airflow, dissipating heat passively.

Cooling drum is designed to big size for high cooling efficiency and low operation cost. While this refers to upstream cooling, it hints at MPMtek’s broader approach to thermal considerations across their systems.

Compatibility with Other Powder Coating Equipment

Integration with Feeders, Classifiers, and Collectors

Chamber design must consider upstream feed consistency and downstream classification accuracy. If the crusher outputs inconsistent sizes or flow volumes, classifiers struggle to do their job effectively.

A good crushing chamber complements other systems by synchronizing speed, volume, and size distribution.

Effects on Overall Production Line Efficiency

Mismatch in equipment capacity or outlet alignment can bottleneck production. Even small misalignments at the chamber outlet can cause blockages or delays in downstream systems like chip collectors or powder classifiers.

MPMtek focuses on providing complete system solutions, rather than isolated units. This is reflected in the integrated design characteristics of its multiple product lines serving powder coating manufacturing.

Design Considerations Based on Application Needs

Factors to Evaluate When Selecting a Chamber Design

Before choosing a chamber type, evaluate:

- Target particle size distribution (tight vs. wide)

- Material behavior under stress (brittle vs. ductile)

- Thermal sensitivity (especially with thermoplastics)

- Required throughput per hour

Also consider whether you need modularity for frequent changeovers or dedicated setups for single material runs.

Customization Options for Industry Specific Requirements

Some applications demand adjustable liners or interchangeable internal profiles. These features allow manufacturers to switch between formulations without investing in multiple machines.

Compact construction can save 65% working area than other series cooling crusher offers further flexibility where floor space is limited—another key consideration when customizing equipment layout.

FAQs

Q1: What’s the difference between flat and curved crushing chambers?

Flat chambers provide uniform crushing but may limit flow; curved designs improve internal circulation and reduce blockages.

Q2: Can I adjust particle size after installation?

Yes, many crushers offer adjustable liners or gap settings to modify chip size based on material needs.

Q3: How does chamber design affect energy use?

Efficient chambers reduce friction losses and improve force transfer during crushing—meaning lower energy per kilogram processed.

Q4: Is there a standard chamber shape for all powder coatings?

Not really—thermosets may tolerate more aggressive reduction than thermoplastics. Design should match material type.

Q5: Who makes reliable powder coating crushers?

MPMtek is a specialized manufacturer known for its compact cooling crushers and full system equipment for powder coating production.