Getting even air flow is an important but often overlooked part in how well an air cooling belt conveyor works and how long it lasts. Uneven air can mess up cooling. It can also hurt product quality, waste energy, and wear out parts faster. The fix is to improve the design and running of the conveyor system. This helps spread air evenly over the whole cooling belt.

Significance of Uniform Air Intake in Air Cooling Belt Conveyors

Role of Air Intake in Cooling Efficiency

Even air intake makes sure products cool the same way across the belt. This matters a lot in systems like the air cooling belt (rubber). It has cooling rollers, artificial rubber conveyor, crusher and cooling air system. Without even intake, the hot melting material from the extruder might cool in spots. This leads to hot areas or parts that stay too warm.

Hot areas cause problems because they change how chips form. You can adjust chip thickness, and size stays the same—but only if the material cools evenly before the crusher. If not, you get odd sizes or bad chips.

Besides that, uneven temperatures can cut down on output. A conveyor set for a certain speed might need to go slower. This lets the poorly cooled spots reach room temperature.

Impact on Conveyor System Performance

Apart from product quality, uneven air intake puts stress on different conveyor parts. Uneven cooling can make the belt expand in odd ways. This affects how the belt tracks and lines up.

Good airflow boosts energy use too. The cooling fans and systems don’t need to run extra hard to fix issues. So, they use less power. In both air cooling belt (rubber) and air cooling belt (slat) models, low power use is a main feature—but that works only if airflow stays balanced.

Reducing temperature differences also shields bearings, seals, and other moving conveyor parts from early wear. This comes from heat changes.

Key Factors Influencing Air Intake Uniformity

Conveyor Design Configuration

Conveyor system design directly shapes airflow patterns. Belt width and length decide how much space the air covers. For instance, wider belts need better spread out duct systems to skip dead spots.

The enclosure shape matters too. If the housing has sharp edges or uneven vents, airflow can get messy or skip some areas completely.

Fan Selection and Placement

Fan type and specs must fit the system’s pressure and amount needs. Even a strong fan can create imbalances if placed wrong.

Bad placement—like fans too near one side—can pull more air through that end. This leaves other spots under cooled. Fans with speed controls or variable drives help keep intake steady under various loads.

Material Properties Being Cooled

The traits of the material play a part too. If you’re cooling thick or odd shaped items, they can block air paths. This creates shadowed spots where air doesn’t reach well.

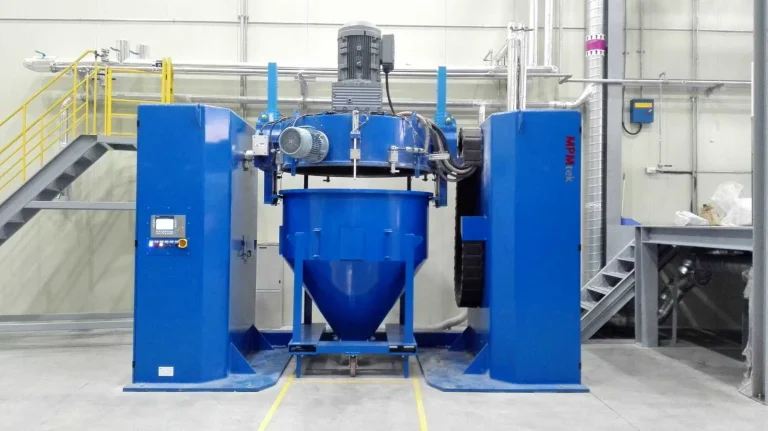

In systems like those from MPMtek, hot melting material from extruder gets rolled into thin sheets of 1-2mm by cooling rollers. So, stacking height and even surface are key to avoid air flow blocks.

Ambient Environmental Conditions

Outside factors like room heat, moisture, or breezes from nearby machines can change intake patterns. If your place sees lots of changes, your system needs to adjust to them.

Design Strategies to Promote Uniform Air Intake

Optimizing Belt Conveyor Layout

Begin with balanced ducting. Even duct setups make sure air hits all areas the same. Keep the conveyor line straight as much as you can—skip sharp bends or quick widenings that mess up flow.

Also, ensure your enclosure seals tight. Air leaks cut down on cooling and upset pressure balance.

Integrating Adjustable Dampers or Louvers

Dampers allow you to tweak air amount in certain sections. This helps with different load amounts or shifts in surroundings. Adjustable louvers can shift airflow on the fly without big changes to the setup.

Adding these lets your system act smart instead of pushing air the same way no matter what.

Using Computational Fluid Dynamics (CFD) Analysis

For new setups or big fixes, CFD modeling gives good info. It simulates airflow in your conveyor design. So, you spot trouble spots—like areas with wild flow or low speed—before you build.

This analysis helps a lot for busy systems like those from MPMtek, a professional manufacturer of powder coating production equipment whose air cooling belts are designed to cool down material on a rubber or stainless steel conveyor to ambient temperature by cooling air.

Operational Measures for Maintaining Uniformity

Monitoring System Performance in Real Time

Put in temperature sensors at many points on the belt and in duct channels. Use this info to watch for changes that might show fan issues, duct clogs, or material buildup.

Changing fan speeds and dampers based on sensor data keeps things best during the process.

Routine Maintenance of Fans and Ducts

Filters, vents, and fan blades pick up dust over time. Clogged filters raise pressure drop, which cuts airflow. In the same way, cracks or loose parts can leak air away from where it’s needed.

Regular upkeep keeps performance steady and stops sudden changes in intake evenness.

Training Operators on System Behavior

Operators need to know how loading affects cooling. Uneven spread of material on the belt can throw off airflow even in a good design.

Train them to spot early signs—like changes in chip size or odd temperatures—and act fast. Get them to tell about problems before they turn into breakdowns.

To ensure optimal cooling efficiency and product quality, it’s crucial to have a well-designed air cooling belt conveyor system. Visit MPMtek today to explore how our cutting-edge systems can enhance your production efficiency and keep your operations running smoothly.

FAQ

Q1: How does uneven air intake affect product quality?

It can lead to inconsistent cooling, causing chips to vary in size and thickness, which impacts overall quality.

Q2: What role do dampers play in air intake control?

They regulate airflow volume in specific zones, allowing for better balance across the belt.

Q3: Can fan placement alone solve intake uniformity issues?

Not always—fan placement must be paired with proper duct design and system layout for optimal effect.

Q4: How often should ducts be cleaned?

Depends on your environment, but typically every 3–6 months to prevent blockages and maintain airflow efficiency.

Q5: Is CFD analysis necessary for small scale systems?

Not always essential, but it’s highly recommended for medium to large scale systems where airflow dynamics are complex.