Leakage in a container mixer might look like a small problem at first, but it can cause big production stops, waste of stuff, and safety risks. Whether you’re dealing with powder coated steel or putting on a gold powder coat finish, keeping the mixer’s sealing setup strong is key for steady work and good results. Stopping leaks isn’t only about fixing issues when they pop up — it’s about figuring out the main reasons and using prevention steps from setup to daily use.

Common Causes of Leakage in Container Mixers

Seal Degradation Over Time

One of the top reasons for mixer leaks is the slow wear of seals. With ongoing use, seals face rubbing and hot conditions.

Coking comes from the hot air breakdown of chain oil. Water, steam, sour or basic items, and tiny bits can speed up this breakdown and boost coking. This idea works for seals in mixers too, where harsh stuff and high heat can hurt how they work.

In jobs with rough powders or active chemicals — like metal finishes or gold powder coat — the seals are extra at risk. Over time, even good sealing setups will need swaps if not watched closely.

Incorrect Installation Practices

Setup mistakes are a quiet source of many gear troubles. In container mixers, bad alignment during build can lead to uneven push on seals, and that makes tiny openings for stuff to slip out.

Tightening bolts too much might feel like a sure way to hold things firm, but it can squash gaskets or bend O-rings. On the other hand, not tightening enough fails to make a solid seal. Using wrong torque gear or skipping the maker’s suggested order raises the chance of leak spots during runs.

Incompatibility Between Materials and Mixer Components

Stuff matching is often missed during gear prep. In powder coating tasks, especially with strong mixes used on powder coated steel or with metal adds, reactions between seal stuff and the product can wear down sealing spots.

Picking mismatched metals can also cause electric corrosion at join points. Plus, different heat growth — where parts swell at various speeds under warmth — can form tiny gaps over time. These are hard to see but let fine powders get away.

Strategies to Prevent Leakage in Container Mixers

Implementing Routine Maintenance Schedules

Steady upkeep is your main shield against leaks.

- Regular checks of seals, gaskets, and fittings help gear last longer.

- Oiling and wiping stop buildup that might lead to leaks.

- Planned swaps of key parts cut down surprise stops.

Chain oil gets into the rubbing areas between the sleeve and the pin, and between the roller and the sleeve through these gaps. This kind of getting in idea also fits how leaks can start from tiny wear — regular looks catch these early hints before they turn into big troubles.

Ensuring Proper Installation Techniques

Using tuned torque tools is important. Always stick to maker tips for gasket spots and tightening orders. After setup, pressure checks make sure all joins are sealed right before full runs.

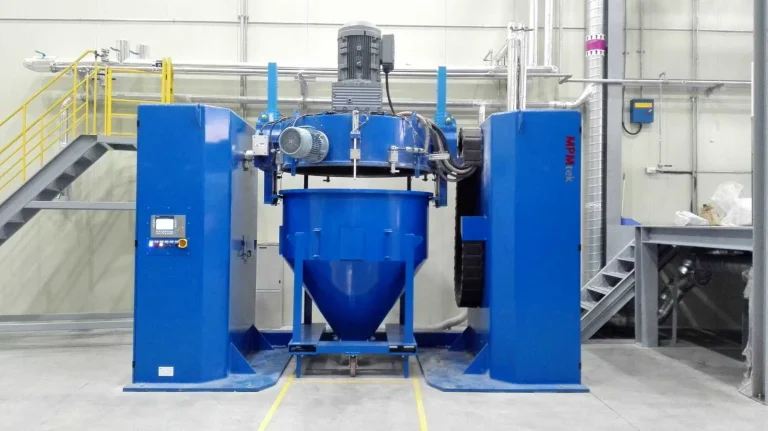

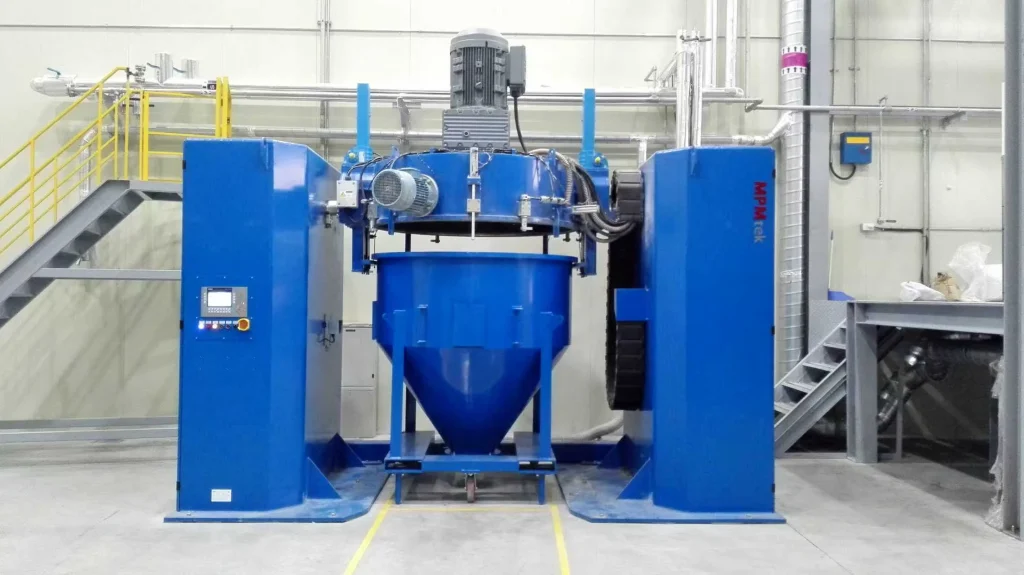

For MPMtek’s container mixer line, which features automatic control by PLC & HMI and double seals for shaft, no powder leakage, no solidified particle, proper setup ensures you make full use of its design benefits.

Selecting Appropriate Materials for Your Application

Each powder kind has its own traits. Pick seals that match your exact powders — whether it’s something as fine as gold powder coat or more general powder coated steel materials.

- Use rust proof alloys when handling active or rough mixes.

- For food safe powders or touchy jobs, FDA ok seals might be needed.

- Know the flightiness and heat limits of your stuff: When utilized within a range not exceeding 220℃, polyether oil exhibits minimal coking, low volatility, and good lubrication performance.

Upgrading Equipment with Modern Sealing Technologies

Updating old mixers can greatly cut leak dangers. Think about adding:

- Improved mechanical or double lip seals

- Pressure let out valves to handle inside strain

- Piece by piece parts that make seal changes simple

MPMtek offers high reliability mixers built for flexible off line production. With features like multi containers used to operation, easy to clean and change color and optional cooling water jacket equipped for mixing head, upgrading to such designs can mitigate many leakage related headaches.

Enhancing Staff Competency in Leak Prevention Practices

Technical Training on Equipment Handling and Assembly

Even well made gear can flop if handled wrong. Staff should learn about:

- Spotting early hints of wear or possible leak spots

- Right tightening steps based on part type

- How to take apart and check seals safely without harm

This is extra key in fields dealing with pricey coatings like metallic or gold powder coat finishes.

Promoting Awareness of Material Compatibility Issues

Workers need more than just tool skills — they must grasp chemical mixes too.

Keep fresh chemical resistance lists handy in your place and often teach teams on picking fit materials based on powder type (e.g., roughness, activity).

Establishing Effective Monitoring and Inspection Protocols

Continuous Monitoring During Mixer Operation

Live leak spotting boosts fix time a lot.

- Put in sensors to catch pressure falls or stuff oozing

- Use sight markers around main joins for quick hand checks

This cuts surprise stops and stops dirt in end products.

Periodic Inspection and Documentation Procedures

Set up a book based check system. For spots handling powder coated steel parts or often color switches, adjust lists to fit — this keeps steady quality over groups.

Also note seen problems and fix work to spot repeat trouble zones or bad setup ways.

MPMtek is a trusted industrial supplier dedicated to the research and manufacturing of powder coating production equipment. From efficient container mixers to complete production lines, MPMtek serves all aspects of the powder coating process with precision built machinery engineered for reliability and performance.

FAQs

Q: What is the most common cause of leakage in container mixers?

A: Seal degradation due to wear, temperature, and abrasive materials is the leading cause.

Q: Can improper torque lead to leaks?

A: Yes, over tightening or under tightening fasteners can deform seals or leave gaps.

Q: How often should I inspect my mixer seals?

A: It depends on usage frequency, but monthly inspections are a safe starting point for most operations.

Q: Are all seal materials compatible with metallic powder coatings?

A: No. Always check chemical compatibility charts before choosing seal materials.

Q: Is it worth upgrading older mixers?

A: Absolutely — modern sealing technologies significantly reduce leak risk and ease maintenance.