Sebelum berinvestasi dalam pencampur laboratorium untuk aplikasi lapisan bubuk, satu pertanyaan kritis harus ditangani: bagaimana peralatan yang tepat dapat mengurangi cacat yang mengkompromikan kualitas lapisan? Jawabannya terletak pada pencampuran presisi, kompatibilitas dengan perilaku bubuk, dan desain peralatan yang mendukung skalabilitas dan keamanan.

Dengan berfokus pada faktor teknis ini, produsen dapat secara signifikan meminimalkan masalah seperti selesai yang tidak konsisten, kontaminasi, atau adhesi yang buruk - masalah lapisan bubuk umum.

Presisi pencampuran langsung berdampak pada kualitas lapisan

Distribusi Partikel Konsisten Meningkatkan Keseragaman Produk

Ketika datang ke lapisan bubuk, bahkan inkonsistensi terkecil dalam pencampuran dapat menyebabkan cacat lapisan yang terlihat. Distribusi pigmen dan aditif yang tidak rata sering menyebabkan berwarna-warni, tingkat gloss yang tidak konsisten, atau pewarnaan yang tidak teratur. Ketidaksempurnaan visual ini secara langsung mempengaruhi tingkat penerimaan produk dan kepuasan pelanggan.

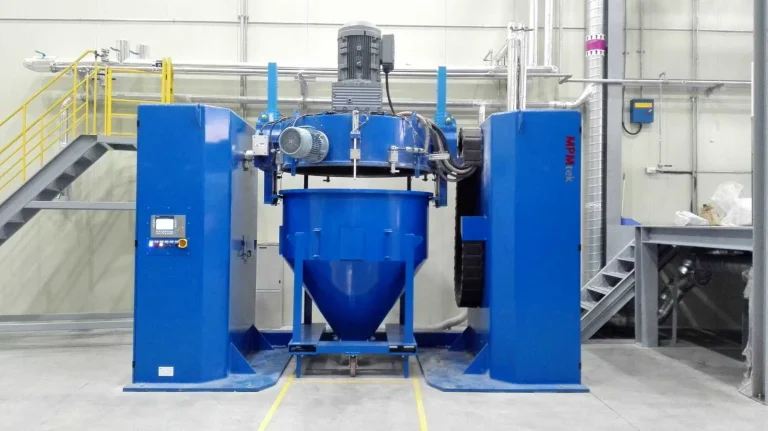

Pengcampur laboratorium yang dirancang untuk homogenitas memainkan peran penting di sini. Kontainer yang dimuat dengan bahan baku didorong ke stasiun kerja asli, untuk diangkat, terhubung dan dikunci ke kepala pencampuran secara otomatis. Bahan baku harus dicampur homogen dengan mengaduk dan penghancur kecepatan tinggi sementara kepala pencampuran miring 180 derajat ke posisi kerja.

Lingkungan pencampuran yang dikendalikan dan menyeluruh ini memastikan bahwa setiap partikel dilapisi dan tersebar secara merata, mendukung pengisian elektrostatik seragam selama aplikasi dan menghindari selesai yang tidak konsisten - masalah lapisan bubuk yang sering terjadi.

Kontrol halus dari parameter pencampuran mengoptimalkan efisiensi proses

Tidak semua bubuk berperilaku sama. Beberapa lebih kohesif, yang lain lebih mengalir bebas, membutuhkan kontrol yang tepat atas kecepatan dan durasi pencampuran. Mixer laboratorium yang baik memungkinkan operator untuk menyesuaikan parameter ini dengan mudah, menyesuaikan proses dengan bahan yang berbeda.

Mixer wadah secara otomatis dikendalikan oleh PLC & amp; HMl, yang menyediakan pilihan yang dapat diprogram untuk waktu, kecepatan, dan urutan - memastikan reproduksibilitas di berbagai batch dan kontrol yang lebih baik atas ketebalan lapisan. Itu adalah langkah utama untuk menghilangkan cacat lapisan yang berasal dari variabilitas proses.

Desain Mixer Lanjutan Meminimalkan Risiko Kontaminasi Silang

Kontaminasi silang antara batch adalah ancaman diam di laboratorium lapisan bubuk. Hal ini dapat menyebabkan pergeseran warna yang tidak terduga, tekstur yang tidak konsisten, atau penurunan adhesi. Multi-kontainer yang digunakan untuk operasi, mudah dibersihkan dan mengubah warna adalah fitur yang mengurangi risiko ini secara signifikan.

Juga, segel ganda untuk poros, tidak ada kebocoran bubuk, tidak ada partikel padat memastikan tidak ada bahan sisa yang ditinggalkan antara berjalan - persyaratan penting untuk mematuhi protokol jaminan mutu.

Skalabilitas Mendukung Transisi Dari Lab ke Produksi

Kompatibilitas dengan skala pilot dan produksi

Pengujian di laboratorium hanya setengah pekerjaan. Tantangan nyata terletak pada mentransfer hasil tersebut ke produksi tanpa memperkenalkan cacat lapisan bubuk baru. Pengcampur kontainer dari seri CMR adalah peralatan fleksibel untuk produksi dengan pemanfaatan tinggi, yang berarti dinamiknya mencerminkan peralatan skala penuh - meminimalkan kejutan selama skala-up.

Apakah Anda’ pindah dari CMR-10 ke model kapasitas yang lebih tinggi seperti CMR-50, prinsip operasi tetap konsisten, mengurangi kesalahan formulasi atau perilaku bubuk yang tidak terduga selama produksi.

Fleksibilitas Ukuran Batch Mendukung R & amp; D Kebutuhan

Tahap awal R & amp; D melibatkan banyak trial-and-error. Mampu mencampur batch uji kecil tanpa membuang-buang bahan mahal sangat penting. MPMtek menawarkan beberapa pilihan kapasitas seperti:

| Model | Kapasitas kontainer (L) | Kapasitas kerja (L) |

| CMR-10 | 10 | 8 |

| CMR-30 | 30 | 24 |

| CMR-50 | 50 | 40 |

Fleksibilitas ini mendukung siklus iterasi yang lebih cepat sambil menjaga biaya rendah - terutama penting saat menjelajahi formulasi atau aditif baru.

Desain Modular Memungkinkan Integrasi ke Sistem yang Lebih Besar

Mixer laboratorium Anda seharusnya tidak menjadi alat yang terisolasi; harus terintegrasi dengan mulus ke dalam garis lapisan bubuk yang lebih luas. Sistem seperti yang ditemukan di Lab Line MPMtek memungkinkan koneksi dengan proses hilir seperti ekstrusi dan penggilingan.

Mixer yang terhubung dengan unit makan, dosis, atau ekstrusi merampingkan alur kerja dan dapat ditingkatkan untuk otomatisasi tanpa mengganti unit inti. Itu adalah pemikiran jangka panjang.

Perilaku Aliran Bubuk Mempengaruhi Kinerja Peralatan

Geometri Mixer Mempengaruhi Pola Gerakan Bubuk

Bentuk internal mixer secara langsung mempengaruhi bagaimana bubuk bergerak dan berinteraksi. Geometri yang buruk menyebabkan zona mati dan pemisahan bahan - keduanya adalah sumber cacat lapisan. Mixer yang dirancang dengan baik mempromosikan waktu tinggal seragam dan pola aliran yang konsisten.

Memilih geometri yang tepat membutuhkan pemahaman karakteristik bubuk Anda. Bubuk yang mengalir bebas berperilaku sangat berbeda dari yang halus atau lengket.

Mekanisme Agitasi Menentukan Efisiensi Campuran

Bubuk yang berbeda membutuhkan tindakan pencampuran yang berbeda:

| Mekanisme | Terbaik Untuk |

| Paddle | Tujuan umum, aliran moderat |

| pita | Campuran halus |

| Bajak | Pencampuran agresif dari campuran yang keras |

Terlalu banyak kekuatan dapat merusak partikel; terlalu sedikit memungkinkan kumpulan atau dispersi yang buruk. Insinyur MPMtek sering membantu di bidang ini: MPMtek insinyur sering membantu klien dalam pencocokan sifat bubuk dengan mixer yang cocok.

Karakteristik Bubuk Mempengaruhi Kompatibilitas Peralatan

Faktor-faktor seperti flowability, distribusi ukuran partikel, dan kohesivitas harus sejajar dengan desain mixer. Jika bubuk Anda dengan mudah berkekumpulan atau memiliki masalah elektrostatik, menggunakan mixer yang tidak cocok hanya akan memperkuat masalah lapisan bubuk tersebut.

Fitur Keselamatan Mengurangi Risiko Operasional di Pengaturan Laboratorium

Desain Sistem Tertutup Memastikan Perlindungan Operator

Bekerja dengan bubuk halus berarti debu - dan debu dapat berbahaya jika dihirup atau jika mudah terbakar. Sistem perlindungan keselamatan yang komprehensif dan desain tertutup mengurangi paparan operator dan menjaga area kerja yang lebih bersih.

Perlindungan beban berlebihan mencegah kerusakan peralatan dan downtime

Sensor yang mendeteksi beban yang berlebihan atau resistensi mekanis membantu mencegah kerusakan selama kondisi yang tidak normal. Fungsi pemadaman otomatis melindungi motor dan komponen mekanis, memastikan umur layanan yang diperpanjang dan pemeliharaan yang tidak direncanakan.

Pemeliharaan Mudah Mengurangi Bahaya Operasional

Akses cepat untuk pembersihan dan inspeksi mengurangi waktu turnaround antara uji coba. Akses bebas alat ke komponen utama menyederhanakan rutinitas pembersihan - fitur kecil tetapi berharga yang membantu menjaga kinerja yang konsisten.

Otomatisasi Meningkatkan Akurasi dan Reproduksibilitas dalam Proses Pencampuran

Kontrol yang Dapat Diprogram Meningkatkan Reproduksibilitas

Antarmuka digital menghilangkan kesalahan manusia dengan menyimpan profil untuk formulasi yang berbeda. Alih-alih mengandalkan pengaturan manual, Anda mendapatkan hasil yang dapat diulang setiap kali - terutama berguna ketika melakukan transisi resep dari laboratorium ke produksi.

yang pengcampur wadah secara otomatis dikendalikan oleh PLC & HMl, memungkinkan dokumentasi untuk audit kualitas dan memastikan pelacakan proses.

Pemantauan jarak jauh meningkatkan fleksibilitas operasional

Anda tidak perlu berdiri di sebelah mesin sepanjang hari. Pemantauan real-time memungkinkan deteksi awal anomali - membantu Anda bertindak sebelum masalah kecil menjadi cacat lapisan bubuk utama.

MPMtek mengintegrasikan solusi digital ke dalam mixer laboratorium untuk mendukung praktik Industri 4.0, sehingga Anda’ Anda tidak hanya membeli peralatan - Anda meningkatkan infrastruktur digital Anda.

Memilih Mitra yang Tepat untuk Solusi Peralatan Lapisan Bubuk

Keahlian Di Seluruh Rantai Produksi Lapisan Bubuk Menambahkan Nilai

Pemasok yang berpengetahuan melakukan lebih dari sekedar menjual mesin - mereka menjadi mitra dalam kesuksesan Anda. Pemasok seperti MPMtek menawarkan wawasan tentang bagaimana keputusan skala laboratorium mempengaruhi kinerja lini penuh, mengurangi tebakan selama seleksi peralatan dan meningkatkan konsistensi lini.

Dukungan jangka panjang meningkatkan pengembalian investasi

Berinvestasi dalam layanan dukungan yang dapat diandalkan membuat perbedaan besar dari waktu ke waktu. Tim teknis MPMtek menyediakan konsultasi berkelanjutan berdasarkan kebutuhan produksi yang berkembang, membantu klien beradaptasi saat lini lapisan bubuk mereka tumbuh lebih kompleks atau meningkatkan produksi.

FAQ (Pertanyaan umum)

T: Apa yang menyebabkan cacat lapisan bubuk umum?

Pencampuran yang tidak konsisten, kontaminasi, aliran bubuk yang tidak tepat, dan desain peralatan yang buruk adalah penyebab utama.

T: Bagaimana mixer wadah membantu mengurangi cacat?

Dengan memastikan pencampuran homogen, meminimalkan risiko kontaminasi, dan menawarkan kontrol yang dapat diprogram untuk pengulangan.

T: Bisakah mixer laboratorium meningkat untuk penggunaan produksi?

Ya - model seperti seri CMR MPMtek dirancang untuk mencerminkan perilaku peralatan skala penuh.

T: Mengapa perilaku aliran bubuk penting dalam pemilihan mixer?

Karena bubuk yang berbeda membutuhkan mekanisme agitasi khusus dan geometri kamar untuk memastikan pencampuran seragam.

T: Apakah pencampur laboratorium MPMtek aman untuk bubuk terbakar?

Ya fitur sistem perlindungan keselamatan yang komprehensif memastikan kepatuhan dengan standar keselamatan untuk lingkungan laboratorium.